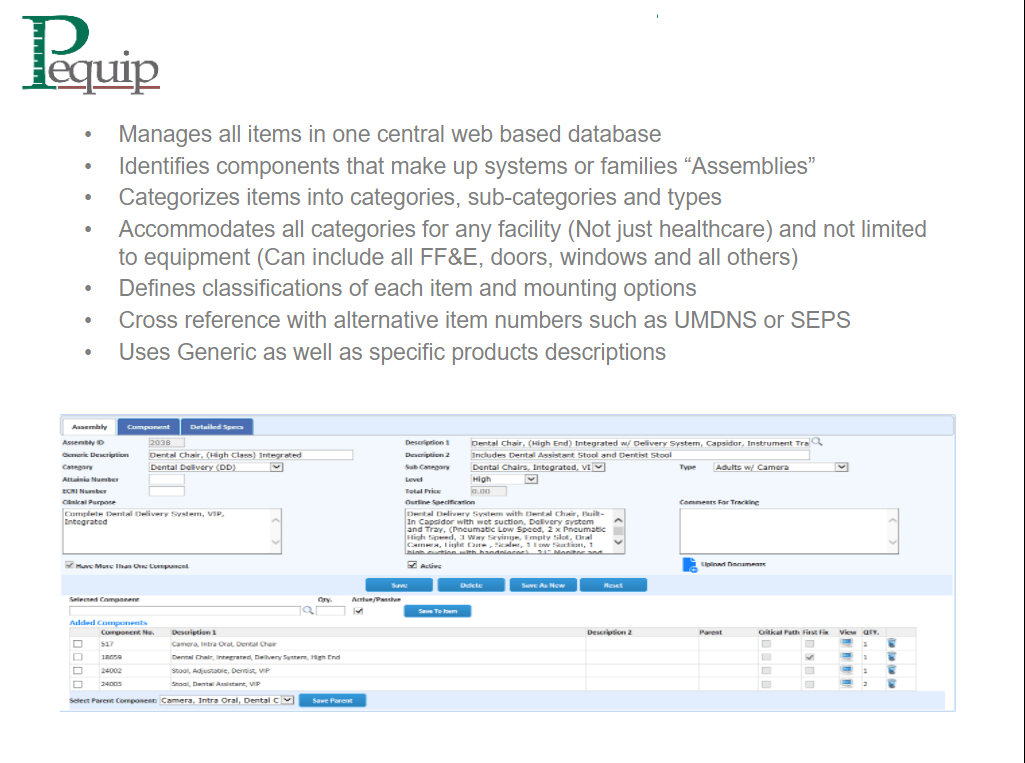

Utilize our Assembly / Components tables and menus where all the products data are stored in the database along with their categories, classifications, attributes, specifications, plug-ins, active manufacturers, mounting, physical characteristics, standard and optional accessories, etc. treats each item as an “Assembly” with “Components”. This is consistent with how REVIT works having Families with individual components to make up a complete system. An Assembly can only have one Component or can have a group of multiple components comprising a complete unique system. Each component AutoCAD block or REVIT model is stored in the Component Menu along with other documents that facilitate the integration with the design drawings.

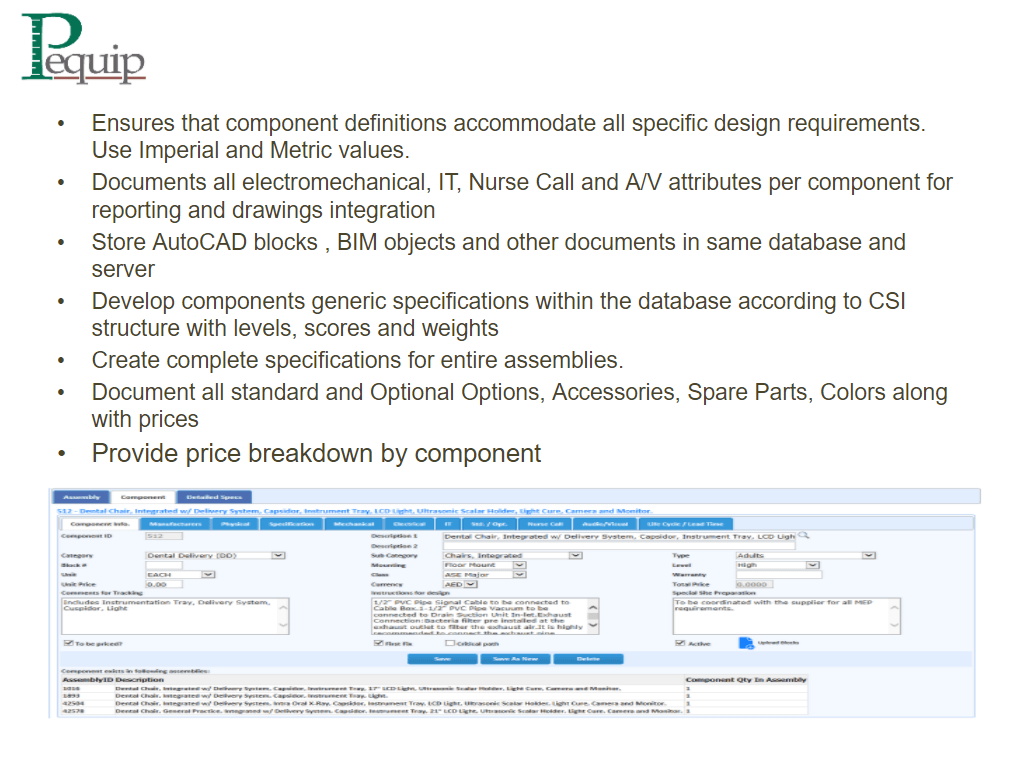

Accommodates Metric and Imperial Values

Pequip can be used by Consultants who base their design on not only metric but also imperial values. The conversion tables are built-in for dimensions and weight measurements. Unique descriptions can be assigned that will differentiate products between HTM and other standards because quantities can be assigned to medical gases per component.

Unique Identifier Numbers according to the Levels of Technology

Different item numbers will be automatically generated identifying low, medium and high technologies thus allowing for the assignment of different budgets and unique attributes for each level of technology per product including manufacturers’ datasheets.

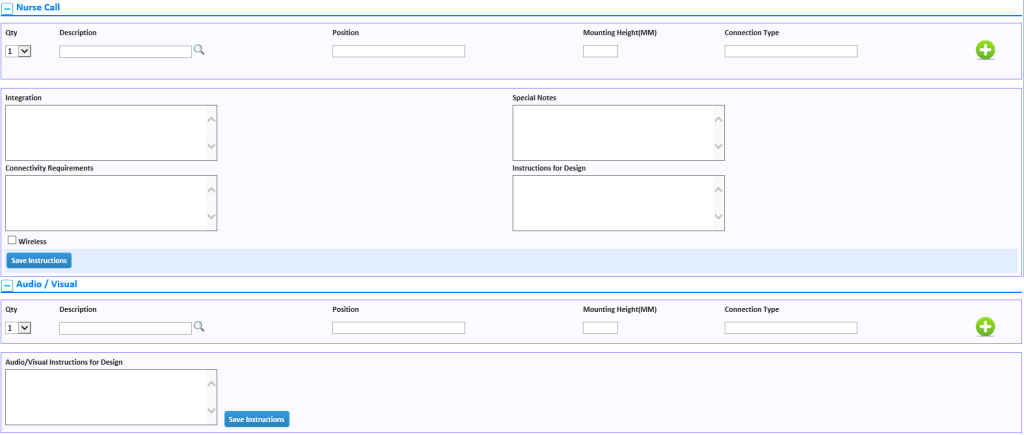

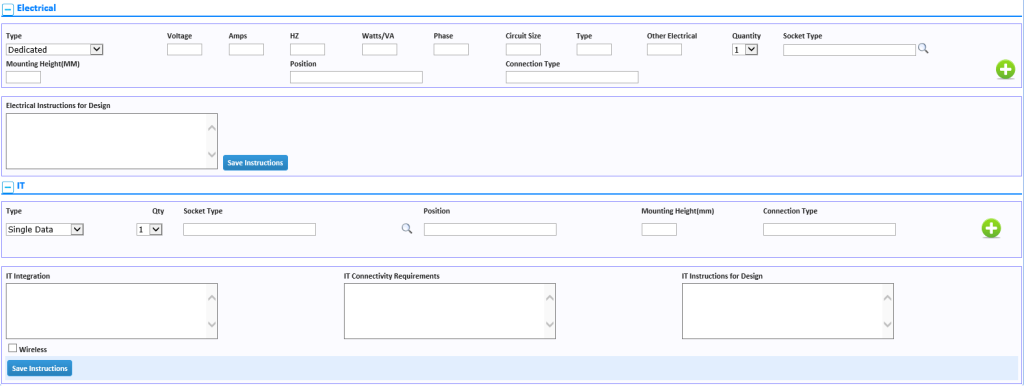

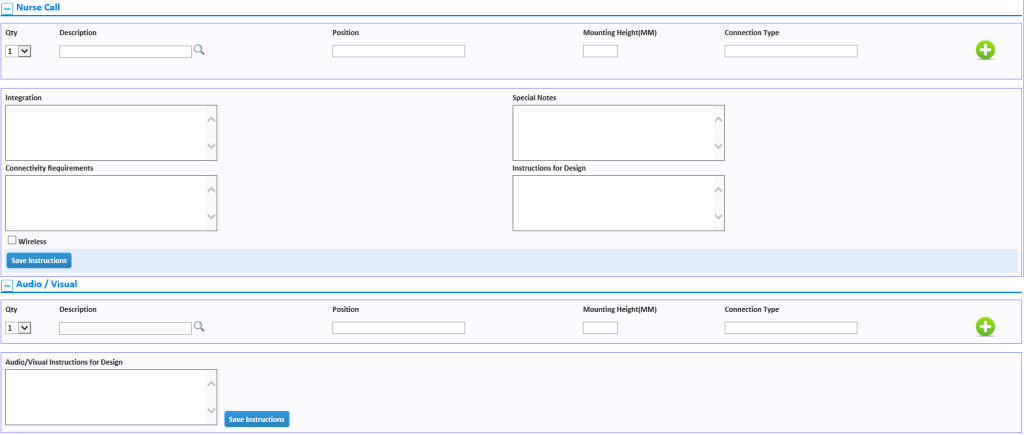

Incorporation of IT Integration Requirements

As more and more medical equipment becomes dependent on IT solutions and applications, Pequip incorporates all IT and audiovisual integration & connectivity requirements which would be embedded in each component for not just reporting purposes but also in the specifications for exporting to the design drawings.

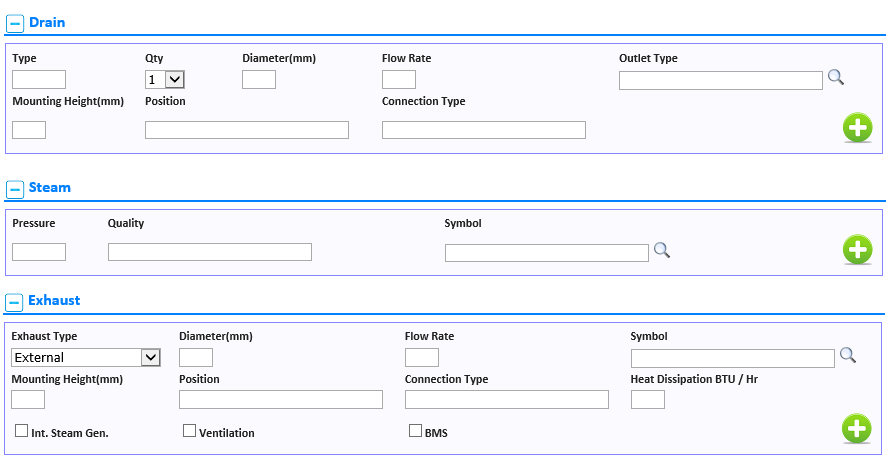

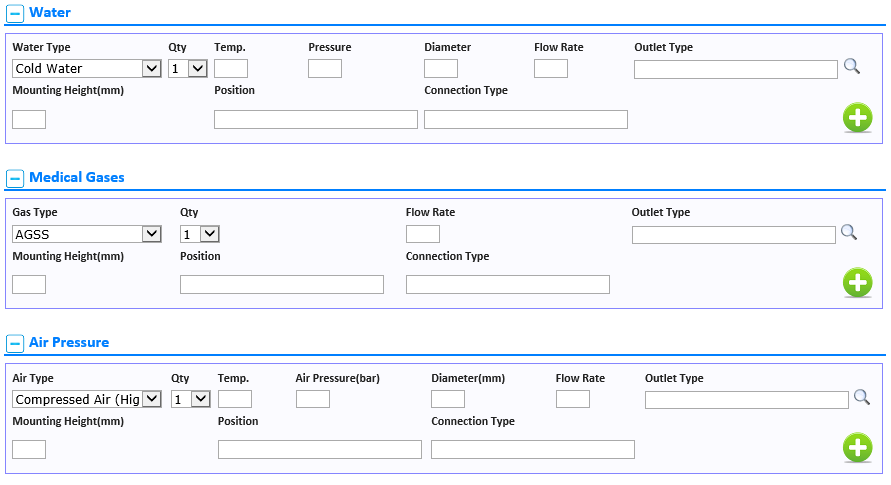

Quantification of Services

Electromechanical, IT and audiovisual requirements per component are quantified thus providing valuable tools to the architects and engineers in knowing the exact requirement per space, department, floor and the entire project. For example, power consumption can now be calculated in the program rather than from the design drawings or manually.Civil, structural, or weight requirements are documented in specific instructions for design comments in the database and on the drawings.

Importation of data to facilitate utilization of post design modules

Some Clients may wish to only utilize and benefit from using Pequip Project Management, Specifications, e-Tendering, Tender Evaluation, e-Procurement, Execution, and Asset Management Module while maintaining the original third party independent AutoCAD or REVIT design.

Pequip has a table in the Admin Module where the original Consultant’s item numbers will be cross referenced against Pequip’s database item numbers. An Excel type table is available to import all departments and rooms to the Pequip project database once a new project is manually set-up in the Project Management Module.

Another Excel table is available to import new assemblies and components along with their attributes directly to the Products Management Module. Once these tables are completed, the users can attach all Excel tables for the original room equipment list using the original item numbers in a table format available in the Admin Module. The System Administrator can then execute the importation of all information into the P Equip databases and the users will be able to proceed utilizing all other modules including printing all reports that will show the original Consultant’s ID numbers.

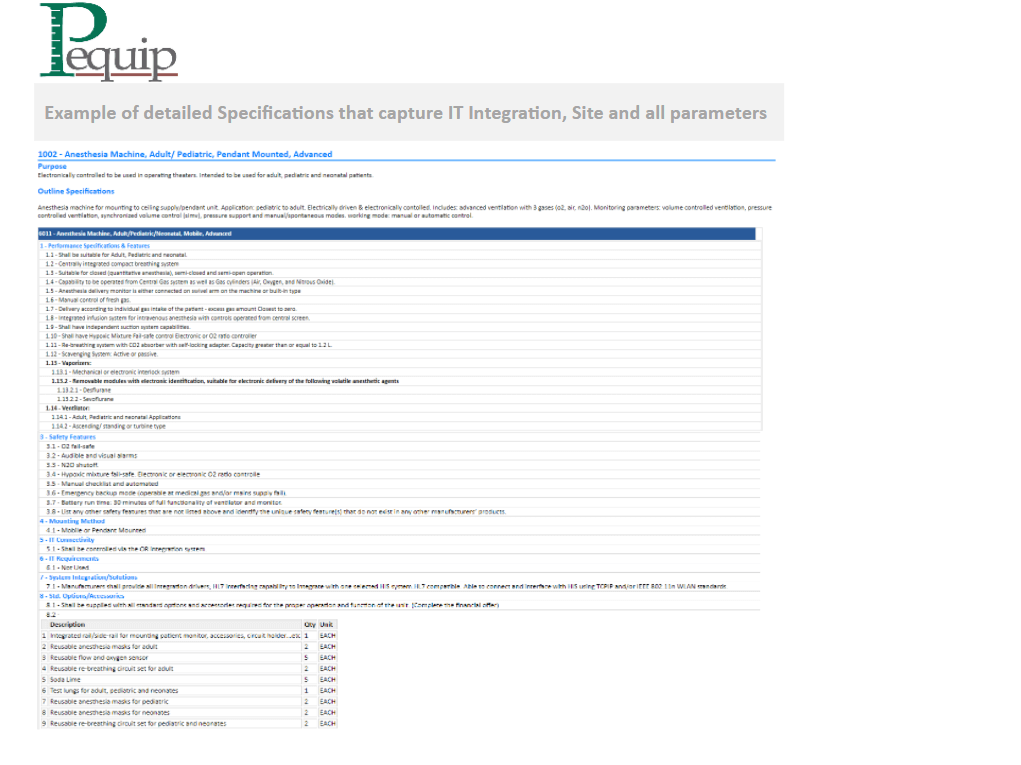

Flexibility in Basis of Design or Generic Specifications

While specifications can be developed to be predominantly generic in nature to apply to multiple manufacturers, Pequip can accommodate international practices in basing the design on specific preselected manufacturers. The Specifications can be generated in one mouse click that would populate data from different section thus creating a comprehensive document including electromechanical requirements, IT Integration, warranties, manufacturers, options and accessories and physical characteristics, etc. Specifications can be customized for each project and published in different formats such as CSI.