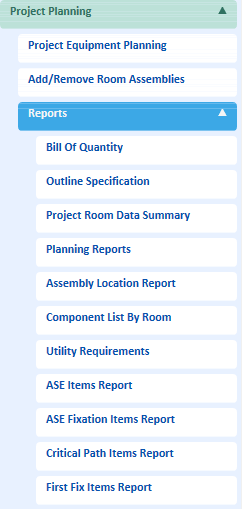

Populating items or assemblies in each room is performed in the Pequip Planning Module. Rooms can be automatically populated by importing a project, a department or a room from another project or from a template. Deletion of items in a room is also performed in the same menu. The user can assign the quantities per phase of items expected deliveries or as existing items in the project resulting from transfers from other estates.

A helpful feature of Pequip is the ability to add or delete an assembly to multiple rooms in the project in one simple screen.

Partial List of Benefits:

- Applying the concept of Components and Assemblies (Unions) will ensure that each component attributes will be captured and will be reflected independently on the design drawings. Building assemblies like cabinets and large systems will avoid creating new item descriptions that say “This component is part of another item” and will facilitate procurement from the proper source in order to save cost.

- Accessing and editing component information from the planning menu will save time from needing to switch screens to the products management menu.

- Being able to add or delete an item from multiple rooms will save time and ensure standardization in programming.

- Once the user’s works on one or more projects in Pequip, irrespective if the subscription is for a single project, all projects information from previous projects will be retained in the independent users database account. This will allow for copying old projects, departments or rooms into the new project, thus avoiding starting from scratch. This is in addition to being able to copy templates that are developed by the individual accounts or from the global templates, as well as importing Excel spreadsheets to the database.

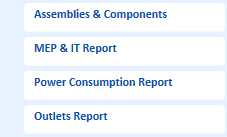

- Incorporating device integration requirements and IT requirements of the equipment during the planning stage will ensure that the facility will be designed to accommodate all IT active and passive components.

- Instead of relying on BIM applications to generate BOQ, REL and other reports, these reports will be readily available in the planning module including calculations of electrical consumption for all equipment.

- By cross referencing the Pequip item numbers with the original item numbers supplied by the Owner, customers will benefit from being able to display the original item numbers.

- Transitioning from generic planning to detailed planning incorporating more specific descriptions with details such as mounting requirements will ensure consistency of information in accordance with the project brief.

- By having electronic specifications built-in the planning module, customers will benefit from developing generic specifications that are customized for each project.